At a basic level, a bill of materials (BOM) is a list of the components, parts, materials, and assemblies needed to build an individual product. Sometimes referred to as a product structure, the BOM describes each item’s quantity and identity (name/number), as well as any relevant specifications such as size or weight.

Manufacturing companies use bills of materials (BOM) to track the components needed to create an end product, plan production schedules efficiently, maintain quality control, manage inventory, and track product and component stock for ordering purposes.

Enhancing Manufacturing Efficiency with Zoho’s Composite Items & BOMs

One of the reasons the Zoho platform is so popular among manufacturing businesses is its ability to easily generate and track these BOMs through the all-in-one Zoho Inventory suite.

That said, the language Zoho uses is a bit different than what you may be used to. Instead of a “bill of materials,” Zoho uses Composite Items, which are a combination of several items that work together to create a single product. For instance, an electronic device may contain batteries, wires, chipsets, and plastic components. To build the final device, all these individual parts need to be assembled.

In Zoho Inventory, you would define a Composite Item for the electronic device and then list all the components that make up the device—batteries, wires, chipsets, plastic components—as sub-items. This creates a “bill of materials” that shows what is needed to create one unit of the finished product.

The Benefits of Zoho Inventory Composite Items

Utilizing Composite Items in Zoho Inventory makes production more efficient, lessens the chances of missing items during packaging, and bolsters an organization’s understanding of its inventory. This is particularly advantageous for child items that are used in multiple parent items.

Bundling each piece in Zoho Inventory can also make it easier for you to keep track of and comprehend your stock. For example, Composite Items can be used by producers and distributors for easy assembly—just like a Bill of Materials. If you were building a printer, Zoho’s Composite Items could be used to define all the required elements, including not just the electronics, cables, and ink, but the printer itself as well.

Unsure if Zoho Inventory is right for your business? Contact ZBrains to get a personalized evaluation of your needs.

How to Enable Composite Items in Zoho Inventory

Enabling Composite Items in Zoho Inventory is simple. All you need to do is:

- Navigate to Settings, then Preferences

- Click the Items tab, and a menu will appear

- Check the Enable Composite Items box

- Hit Save to apply the changes, then exit

How to Create Inventory Bundles for Composite Items

In Zoho Inventory, bundling items into Composite Items takes just a few steps:

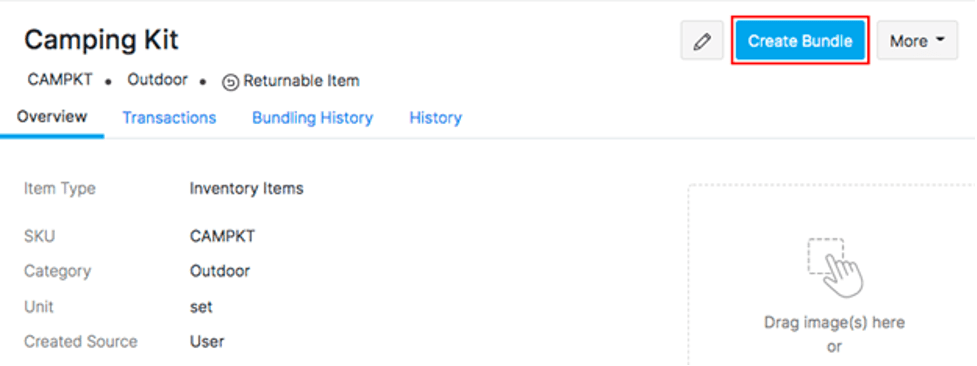

To create a bundle of a Composite Item, go to the Inventory module and open the appropriate Composite Item.

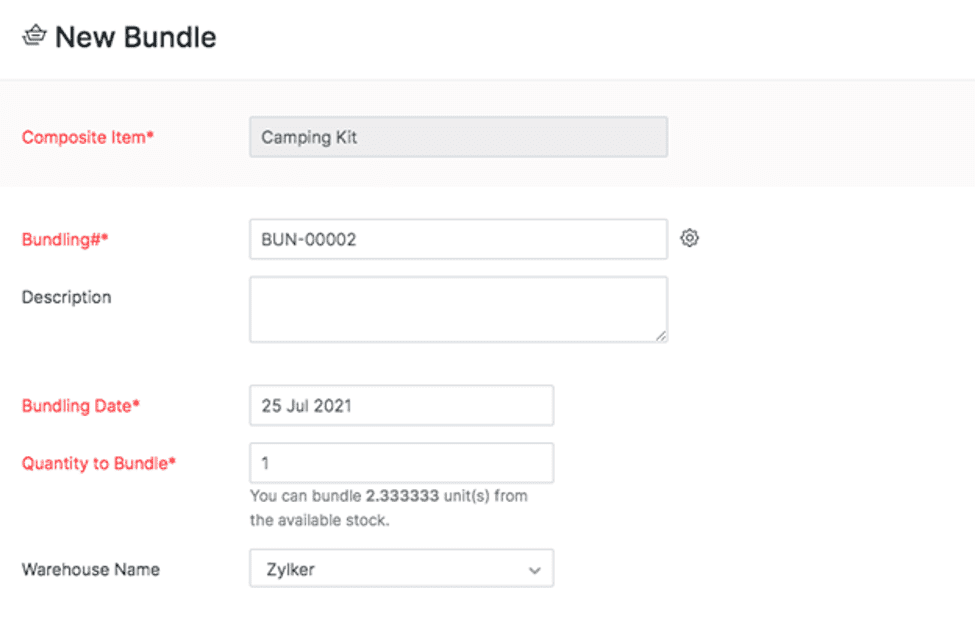

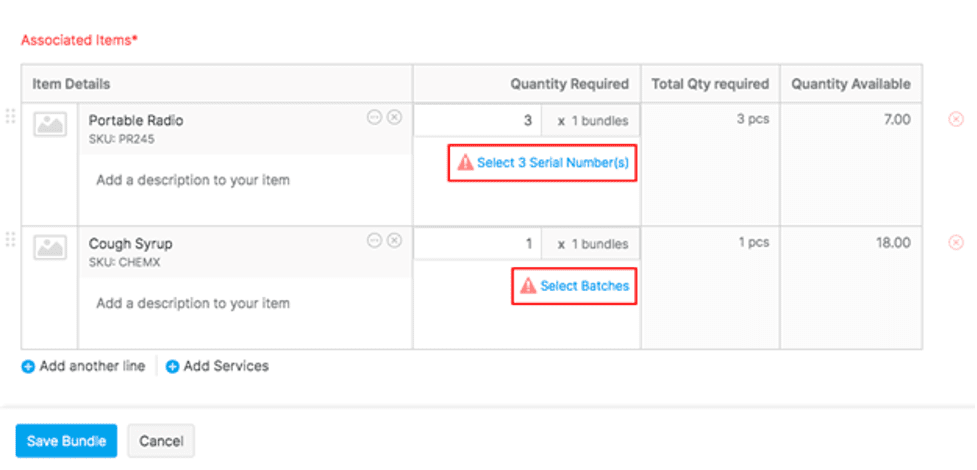

From there, click the “Create Bundle” button and enter the Bundling #, Date, and Quantity you would like to Bundle, as well as any Serial or Batch Numbers for tracked items.

Once you’ve added all your details, click “Save.” The items and services associated with the Composite Item will automatically appear (you can modify these, if needed).

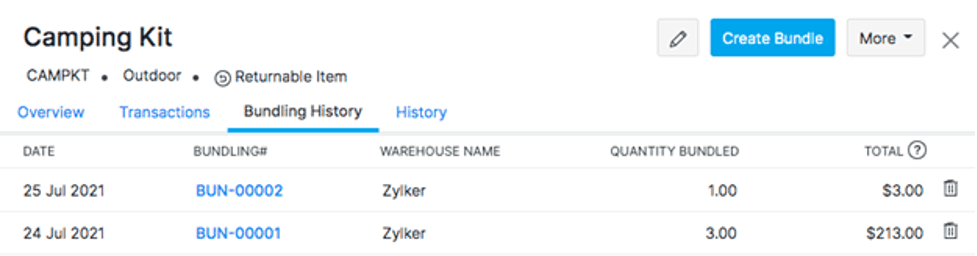

Click on the bundle number in the Bundling History section to view all bundling details.

Advanced Inventory Tracking With Zoho Inventory

Managing so many parts creates a higher risk of mismanagement, but Zoho Inventory’s advanced tracking features keep your Composite Items organized and on track.

Batch Tracking

Batch tracking is a highly-efficient way to monitor and group stock items that have common characteristics (e.g., serial number, expiry date, color, and product association).

Manufacturers can use batch tracking to track production batches across different locations, warehouses, and stores (or keep it all under one roof), saving time by managing all of their items from a single interface.

Moreover, this system provides thorough data analysis, allowing for accurate predictions and estimations related to your inventory levels. With Zoho Inventory, you can easily track items that come in batches with the corresponding manufactured and expiry dates, if relevant. When it’s time for a sale, you can safely select products within their usable period from those same batches.

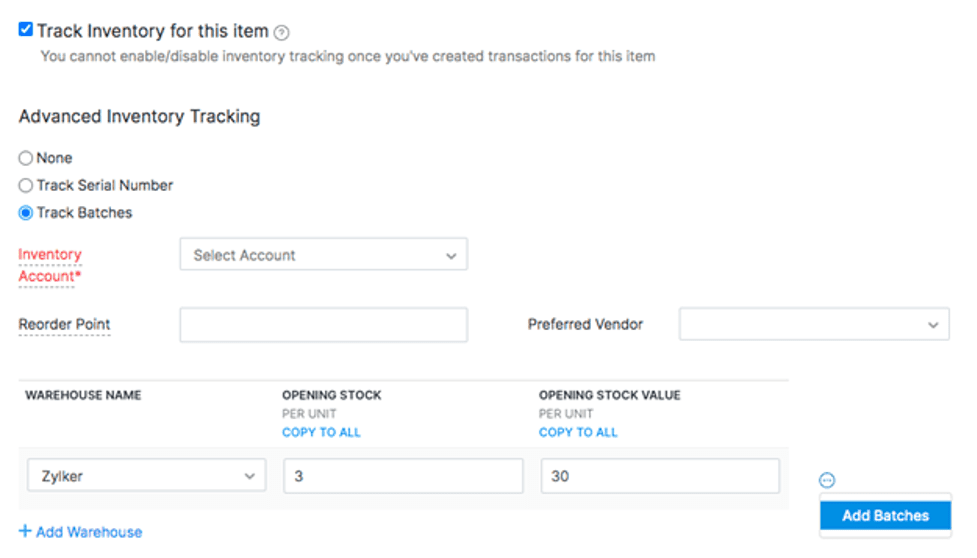

To generate a new item with batch tracking activated, navigate to the item creation page. Fill out all applicable details and then check the box next to “Track Batches” under Advanced Inventory Tracking.

If you have an established opening stock, include any essential batch details in the fields below. If your business takes advantage of multi-warehouse inventory tracking, use the ellipsis icon at the end of each row to add batches for that warehouse, where appropriate.

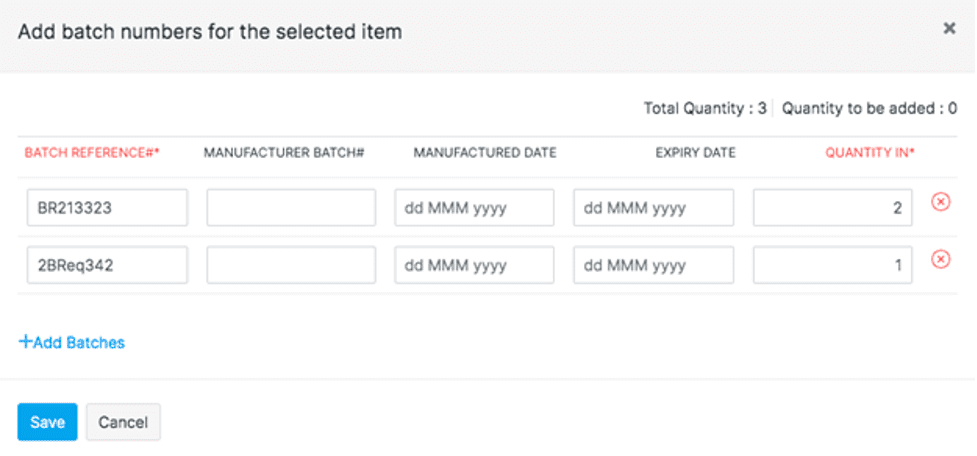

From there, all you have to do is enter the batch details—including its serial number, manufacture date, expiry date, and any other relevant information. Once you’ve entered all the details, click “Save” to add your item with batch tracking enabled.

Serial Number Tracking

Track items with serial number tracking in Zoho Inventory for precise monitoring from factory to consumer.

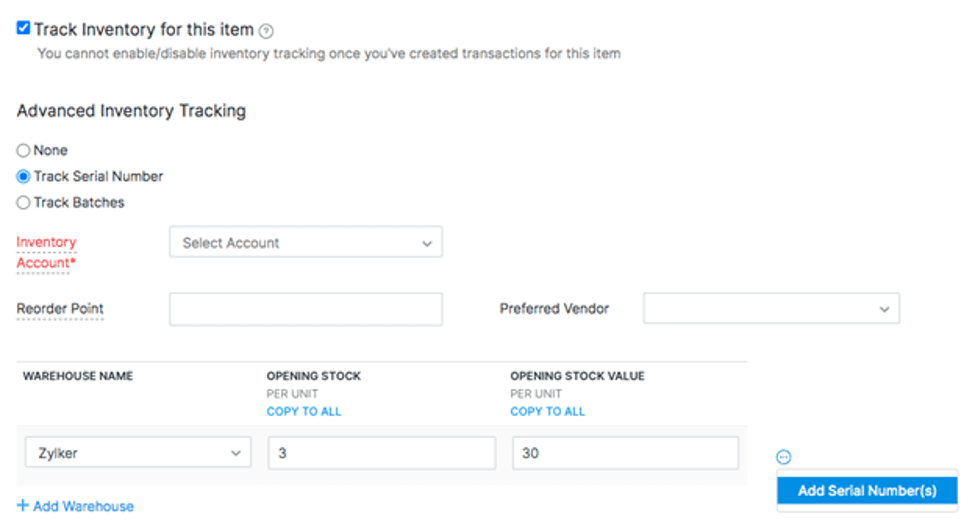

Serial number tracking is especially useful for service-based businesses that need to keep track of replacement parts and components used to perform repairs or maintenance tasks. To enable serial number tracking in Zoho Inventory, go to the new item page and select “Track Serial Numbers” under Advanced Inventory Tracking.

Then, enter the necessary details. Again, if you have opening stock, you can enter the serial numbers in the specified field below. If multi-warehouse enabled, click ellipsis icon beside warehouse row, then ‘Add Serial Numbers’.

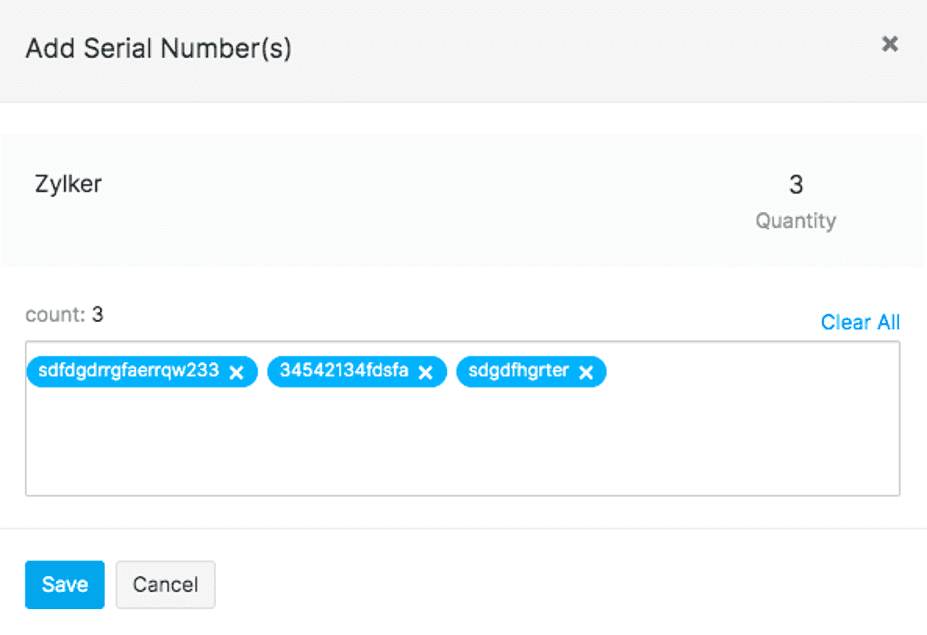

Enter the serial numbers and any other relevant information that you need to track from there. Once you’ve added all the details, click “Save” to finish creating your item with serial number tracking enabled.

Final Thoughts: Zoho Composite Items and BOM (Bill of Materials)

Zoho Inventory streamlines production across multiple locations with Composite Items, Batch Tracking, and Serial Number Tracking.

Zoho Inventory simplifies BOM creation and empowers inventory management and forecasting with powerful features.

Every organization has its own unique tracking needs, creating and tracking Composite Items is just the tip of the iceberg. For more information on generating BOM reports, tracking item components, and managing inventory on a deeper level with Zoho Inventory, reach out to our expert team today.